Products

Home > Handling and storage systems > Back to resultsSilos and fuel supply systems

Silos and fuel supply systems

ITI Engineering designs and manufactures silos for fuel storage and automatic feeding systems for the furnaces.

They must ensure a high degree of reliability and high availability, meaning deadly breaks due to failures, typical when fuel is in the form of difficult handling as with garbage in general.

Another fundamental aspect that the fuel handling system has to guarantee is the ability to achieve a controlled supply of fuel mass, contributing substantially to combustion control.

Fundamental to the realization of these systems is the collaboration with leading companies specializing in the realization of these machines and willing to meet the particular needs of our plants.

Silos:

- Pit with hydraulic push-pull extractors

- Bunker with moovin floors

- Storage building with bridge crane and hydraulic bucket

- Dosing bunkers for powders and fine materials

Transportation:

- Conveyor belts or metal plates conveyors

- Redler type chain, with single or double chain drives

- Screwconveyors for small sized fuels

- Pneumatic transport systems for wooden dust

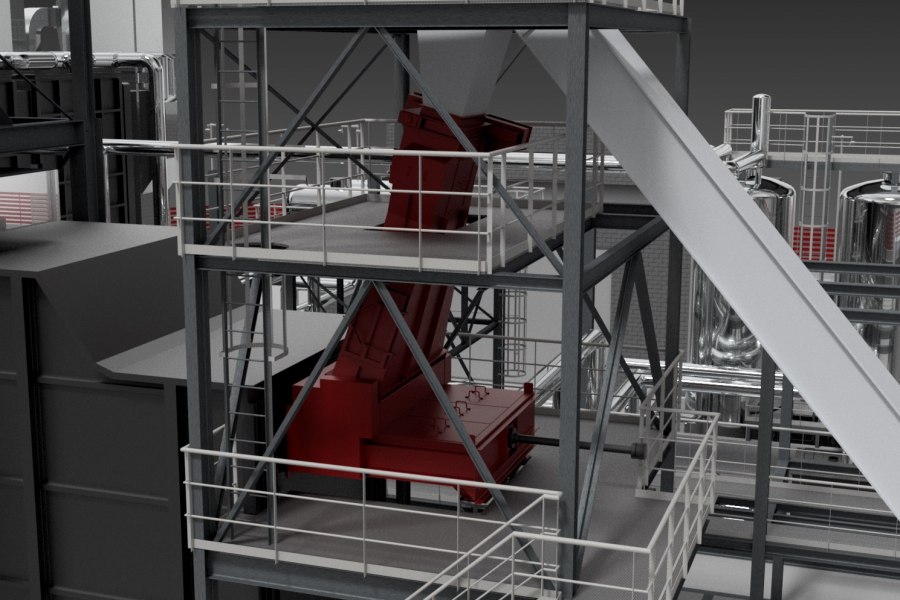

Hopper feeding devices for combustion grids:

Particular mention is the load hopper for the grid. This is a key element in the management and control of the furnace. It must combine the efficacy of the assay with the ability to process fuels with difficult physical characteristics, such as variable batch size or texture that changes, for example, with humidity or inert content.

Our variable speed hydraulic hopper sums up all these features and realizes a reliable dosage of the materials on the grid.

It is controlled by the automatic plant management system and achieves the dosage required by the combustion budgets.